Custom Capabilities

Sciencetech strives to maintain our long term commitment to research and development over a broad spectrum of industries and applications by inventing and developing tailor-made solutions in solar simulation.

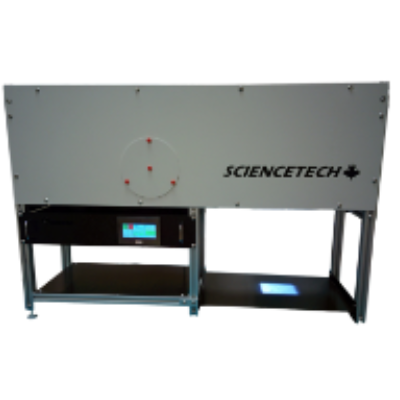

Large Area Illumination

Alongside Sciencetech standard solar simulators, we have also developed systems that are capable of illuminating larger areas in the scale of 1m x 1m and more. These solar simulators can achieve all required industry/ research standards in spectral match, spatial non-uniformity, and temporal stability classifications. The illumination areas are customizable upon request and the spectrum can be in accordance with AM1.5G, AM0, and other special spectral matches to suit each project’s needs.

Sciencetech solar simulator systems employ various optical designs to achieve the required specifications. Xenon short arc lamps, LED technology or metal halide lamps are often used as the base of the illumination system.

Large Area Solar Simulator Uses:

High Spatial Uniformity

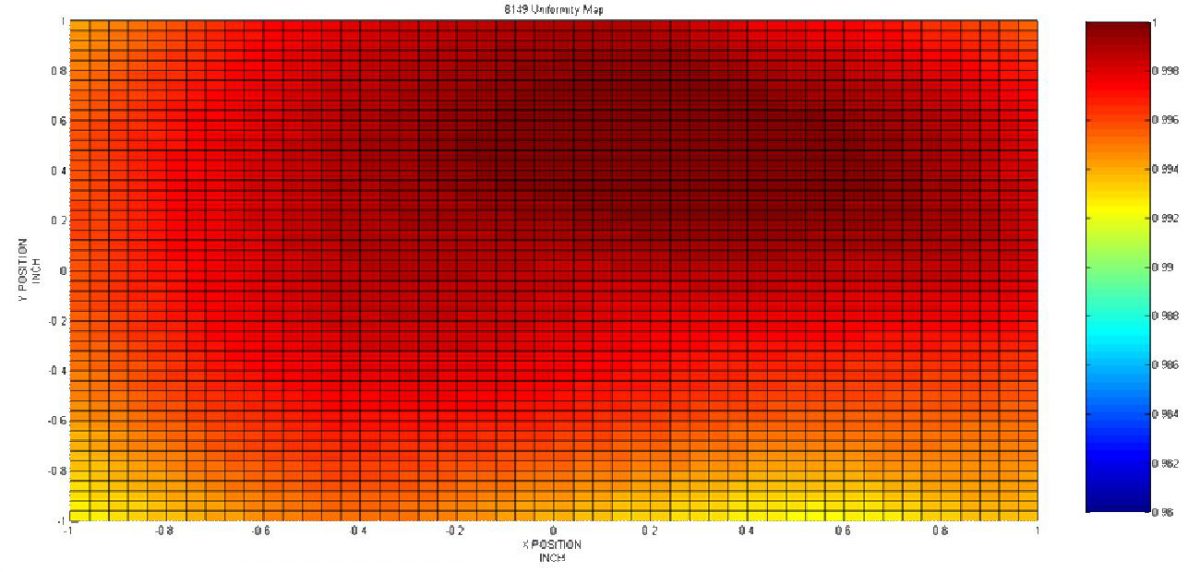

When characterizing solar simulators, spatial uniformity of the illumination area is probably one of the most important parameters assessed. It is also one of the more optically challenging characteristics to be achieved in a solar simulator. Sciencetech employs multiple optical designs to achieve the standards required for spatial uniformity.

Spatial uniformity is defined as the degree of homogeneity in the distribution of the irradiance (optical density) over the illumination area. In other words, how well is the light distributed over the illumination area?

Depending on the illumination area and other optical and mechanical requirements, Sciencetech employ multiple ways of achieving Class A spatial uniformity according to various testing standards.

Sciencetech's Fully Reflective Mirror Design

This optical design is one of our proprietary optical designs to achieve extremely high uniformity without compromising the output optical power. The design does not require lenses or diffusers to make the output uniform at the target plane. As a result, the solar simulator can reach optimal throughput efficiency.

The fully reflective design utilizes a series of mirrors, including a special folding mirror that bends the light without the drawbacks of refractive optics. This allows the solar simulator to produce a higher intensity, uniform illumination at the target.

Lens Assemblies and Homogenizing Light Pipes

Various other optical designs are used to achieve high uniformity. These designs are utilized according to the requirements of the solar simulator and other optomechanical designs of the overall system. Sciencetech uses various lens assemblies and diffusers such as homogenizing light pipes in solar simulators to provide highly uniform light outputs. Almost all our standard solar simulators achieve Class A according to ASTM standards.

Full or Modified Solar Spectrums

The irradiance of the Sun at the Earth’s surface varies under different conditions due to absorption and scattering effects in the atmosphere, and so a number of other constants are important in regards to the irradiance of a solar simulator.

Depending on the atmospheric depth and solar angles, the reference solar spectrum can have different spectral variations. An air mass filter is commonly used to simulate the spectral irradiance of the reference solar spectrum.

Below the atmosphere the radiation emitted from the Sun can be divided into two components: direct radiation that comes from the Sun itself, and scattered radiation coming from the rest of the sky, including a portion reflected back from the ground. Solar simulators are adjusted to imitate the spectral distribution of sunlight for a variety of environments; to do this the spectral distribution from the xenon arc lamp source is altered and refined using Air Mass (AM) filters.

When discussing filters, the direct radiation spectrum is imitated using a direct (D) filter, and the total including scattered sky and ground radiation is matched by using a global (G) filter that imitates both components together.

AM1.5G ASTM E927 Solar spectrum according to standard classification for Solar Simulators for Electrical Performance Testing of Photovoltaic Devices

Most Sciencetech solar simulators use xenon arc lamps, which enables the system to produce a collimated beam of light, similar to that of a 5.8K blackbody, as the sun. AM1.0, 1.5 and 2.0 filters further modify the visible and UV portions of the spectrum for different sea-level conditions, and coupled with the use of high pressure Xenon arc lamps Sciencetech produces Class A standards for our solar simulators.

Sciencetech Engineering has the capability to adjust the solar spectrum for various conditions such as:

Intensity Attenuation

Continuous or incremental attenuation of solar irradiance can be an important requirement for many testing needs. With the use of aperture controls, neutral density filters, and mesh filters, Sciencetech solar simulators have been able to attenuate and adjust the power levels and irradiation to suite multiple research requirements.

High Powered / High Flux Solar Simulators

Sciencetech has developed high powered solar simulators with extremely high irradiation levels, even in the range of 1000s of suns. These high flux solar simulators have the ability to produce tens of hundreds of suns depending on your testing and research needs. Read more on out standard high flux solar simulators and past projects.

High Collimation

Sciencetech has developed highly collimated solar simulators with beams that closely match the solar divergence. Our standard range of highly collimated solar simulators have been used for research and testing purposes in space environment simulation, solar thermal power harnessing and Concentrated Photovoltaic testing industries for many years.

With the use of innovative optical designing and modeling techniques, we have been able to achieve simulated light rays near-close to sun’s divergence angle. Read more about our highly collimated solar simulator projects here.

Other features such as incident angle variability, irradiation attenuation, clean room compatibility and vacuum/ environmental chamber integration are available upon request.

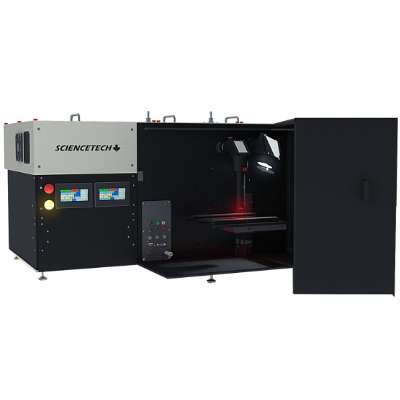

Full Automation with Computer Control

Sciencetech solar simulator systems are fully computer controllable. Our standard solar simulator systems are also touch screen operable through the power supply with PLC control.

We have previously designed automated systems that can vary the incident angles of the solar simulator by manipulating in X, Y, Z axes and in 2 rotational angles providing seamless variability.

Temperature Monitoring

Temperature regulation and monitoring can be included within solar simulator systems to ensure the integrity of controlled environments. Cooling systems can be used to evacuate the heat generated within the system to maintain the required temperature of the overall system.

Many of PV testing equipment such as cell chucks are also temperature regulated in order to test accurate monitoring of efficiencies of photovoltaic cells.

Vacuum Compatibility

Sciencetech have developed three branches of vacuum expertise in the past

Temperature control, connections to vacuum feed-throughs, special coatings etc. can be accommodated to our solar simulator systems upon request.

Notable Sciencetech Systems Using Vacuum Technology.

Sciencetech’s systems can support a 10 torr vacuum within their stainless steel housing and optics chamber.

Large-area Solar Light Source for Large Vacuum Chamber Coupling

Pressurized Chamber for Solar Simulator in Vacuum Environment

Clean Room Compatibility

Cleanroom standards enable a large number of technologically advanced industries to continue their work in a monitored and standardized environment, such as:

Contaminants that are produced by living organisms, machinery, and other equipment can have dire effects in highly sensitive testing environments. Clean rooms are often used to protect contamination-sensitive procedures.

Equipment to be operated in clean rooms also needs to be manufactured in a clean room environment, to prevent the instrument itself from introducing particles into the testing environment.

Clean room requirements are standardized in such a way that the concentration of airborne particles in a clean room is known, limited, and controlled. Clean room standards are classified according to the number of particles found per cubic meter at a specified particle size. The most well-known and often requested standards are classified under ISO 14644-1

Read more about Sciencetech special projects meeting clean room compatibility.